Bei größerer Abnahmemenge

Sonderpreise erfragen (ab 20 Meter)

Hinweis: bei Maßangabe Feet (z.B

5´entsprechen etwa 1,5 Meter)

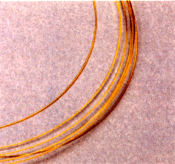

PEEKTM Tubing

1/16", 1/8" and 1.8mm ODs

Available /

Biocompatible, Inert and Easily Cut /

Great for High Pressure Applications

|

|

Upchurch

Scientific® PEEK (polyetheretherketone) polymer tubing is biocompatible,

chemically inert to most solvents, and can be used to replace stainless

steel tubing in most liquid analytical systems. Unlike stainless steel and

titanium tubing, PEEK tubing is flexible and can be easily cut to desired

lengths. PEEK tubing can be used with stainless steel or polymer fittings.

The benefits of PEEK polymer tubing include a high pressure rating (up to

7,000 psi in most cases) and a high temperature rating (maximum continuous

use temperature of 100°C). Additionally, PEEK tubing has a very smooth

internal surface, which causes less turbulance than similar sized metal

tubing. Turbulence can cause remixing of separated sample bands and

dilution of bands by the mobile phase. Of all our polymer tubing materials,

PEEK is the least permeable to gas. |

Upchurch

Scientific PEEK polymer tubing is extruded to the following OD/ID

tolerances: 1/16" OD tubing, ±.001 " for both; 1/8" OD

tubing, ±.003" for both; 1.8mm OD tubing, ±.002" and ±.001

", respectively. The tubing also features excellent concentricity,

with a Total Indicator Runout (TIR) of.003" or less on our 1/16"

OD tubing. In addition, our 1/16" OD tubing is color-coded so

different IDs are easily identified. Color permanence is ensured with the

proprietary process we use in our tubing extrusion.

PEEK tubing offers outstanding chemical compatibility, with very few

solvents interacting with the polymer. Exceptions include DMSO, methylene

chloride, and THF, which can cause mild swelling. Concentrated nitric and

sulfuric acids will degrade PEEK, although our studies show it can safely

withstand 20 - 30% nitric acid, at room temperature, for brief system

cleaning (be sure to remove your column prior to cleaning!).Our 5' length

tubing is rough cut to approximately 5'1 ". A trim cut should be

performed before use, especially for smaller ID tubing. PEEK tubing can be

cut easily with a razor blade. However for a better cut, try our Tubing

Cutters |

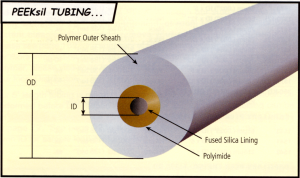

CAPILLARY

PEEKTM

TUBING

360{nn, 510um and 1/32" ODs

Available IDs as .Small as 50µm (.002") |

|

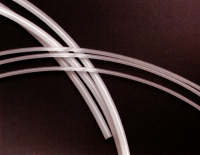

FUSED

SILICA TUBING |

Capillary PEEK

tubing offers all the benefits of larger sized PEEK tubing, while serving

as an excellent alternative to more traditional fused silica and stainless

steel capillary tubing (see Application Note to the right). This

specialized tubing is manufactured in three sizes - 360µm (.0145"),

510µm (.020") and 1/32" (785µm) ODs. These sizes of tubing can

be coupled to many of the products in our Micro Flow chapter and are

recommended for the micro- and nano-scale valves in the High Pressure

Valves Chapter .

Tolerances of the Upchurch Scientific' capillary 360µm and 1/32" OD

PEEK tubing are ±.0005" for both OD and ID. Tolerances for 510µm

ODtubing is ±.001" for both OD and ID. |

As a service

to our customers, we offer cut fused silica tubing in convenient 2m

lengths. Choose from 20, 50, 75, 100 and 150 micron ID sizes, all with 360µm OD. These products are comprised of synthetic fused silica with a

polyimide coating. This tubing is manufactured by Polymicro Technologies.

They rate this tubing to 350°C. The OD tolerance for all 360µm OD fused

silica tubing is ±10µm. The ID tolerances are: ±2µm for the 20µm ID

tubing; ±3µm for the 50µm and 75pm ID tubing; and ±4µm for the 100µm and

150µm ID tubing. For other sizes or lengths of fused silica tubing, please

contact Polymicro Technologies directly. |

SPIRAL-LINK™

TUBING

The coils of our 1/16" OD

x.010" ID Spiral-Link tubing expand and contract, allowing you to

easily move your system components or even make equipment repairs whenever

needed, without the hassle of breaking connections.

Upchurch Scientific® SpiralLink tubing is made of PEEK polymer, a

biocompatible, chemically inert material. Spiral-Links come in six

different lengths. Color permanence is ensured through our proprietary

extrusion process.

Each Spiral-Link ships with two F287 SeaITight™ Fittings. |

|

|

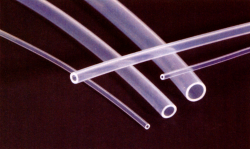

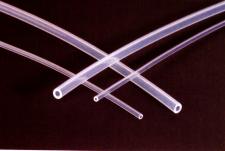

ULTEM®

TUBING

Transparent /

Withstands Repeated Sterilization /

High Durability

Upchurch Scientific has the capability to extrude Ultem (polyetherimide)

tubing. Ultem tubing offers high burst strength, high heat resistance and

excellent chemical resistance against many solvents, lipids, detergents

and disinfectants. In addition, tubing made from Ultem is transparent,

allowing flow to be monitored.This polymer withstands the degradation

effects of various sterilization methods, such as repeated autoclaving,

gamma radiation, EtO gas, and dry heat. Ultem meets IS010993, FDA and USP

Class VI criteria. Please inquire about the availability of Ultem tubing. |

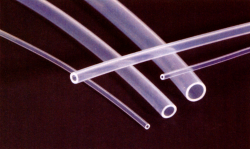

RADEL®

R TUBING

- Withstands up to 12,500 psi (862 bar) /

Transparent and Autoclavable /

1/16" and 1/8" Obs Available

Radial R (polyphenylsulfone) is a mechanically strong and chemically

resistant material, much like PEEK. Radel R is frequently used in medical

applications where repeated autoclave sterilization is performed (tests

show product stability after 1,000 cycles). Racial R tubing is also

transparent, allowing technicians to visually monitor flow through their

instrument. Readily wetted surfaces help keep air bubbles from

accumulating on inner surfaces.

This tubing is available in 1/16" and 1/8" ODs, with OD/ID

tolerances of ±.001 " and ±.003", respectively. This polymer's

high heat deflection value allows it to be used at a maximum operating

temperature of 100°C without losing mechanical strength. |

|

TEFZEL®

(ETFE) TUBING

- Excellent Chemical

Resistance /

Holds Pressure up to 4,000 psi

(276 bar) /

1/16", 1/8", and 1/4" ODs Available

|

|

|

HALAR®

TUBING

- Excellent Chemical

Resistance /

Good for Radiation Sterilization /

1/16" and 1/8" ODs Available |

| Upchurch

Scientific® ETFE (ethyl ene-tetrafluoroethylene) tubing is an excellent

fluoropolymer product offering several benefits over Teflon®. For

instance, the .010" ID x 1/16" OD ETFE tubing can withstand

aqueous pressures to 4,000 psi (276 bar), and up to 1,200 psi (83 bar)

with some amines and inorganic acids. ETFE tubing is also somewhat more

rigid than Teflon tubing and thus exhibits a greater resistance to inner

diameter collapse. The recommended maximum operating temperature for ETFE

tubing is 80°C. |

The

OD/ID tolerances of our ETFE tubing are: |

As

another member of the fluoropolymer family, Halar ECTFE (ethylenechlorotrifluoroethylene)

offers excellent chemical resistance coupled with mechanical strength

superior to Teflon. Tubing made of Halar also outperforms Teflon in

ability to withstand radiation, making it attractive for medical

applications. The OD/ID tolerances of Upchurch Scientific Halar tubing are

both ±.001" for the 1/16" OD tubing and ±.003" for the

1/8" OD tubing. Pressure ratings are presented with the product

listings on this page. The recommended maximum operating temperature for

Halar tubing is 50°C. |

| Tubing

OD |

Tubing

ID |

OD/ID

Tolerances |

| 1/16"

OD |

.010",

.020", .030" |

±.001" |

| 1/16"

OD |

.040" |

±.002" |

| 1/8"

OD |

All |

±.003" |

| 1/4"

OD |

All |

±.004" |

TEFLON®

FEP TUBING

- Great for Moderate-to-Low

Pressure Applications /

1/32",1/16",1/8", 3/16", 1/4" and 5/16" ODs

Available /

1mm, 2mm, 3mm and 4mm ODs Available

|

|

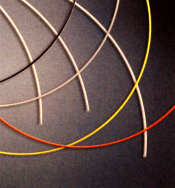

With virtually

identical chemical resistance to PFA at a lower price, Upchurch Scientific®

Teflon FEP tubing is great for general, low pressure applications.

Compared to PTFE, Teflon FEP (fluorinated ethylene propylene) tubing is

held to tighter tolerances and has lower gas permeability.

Much of our Teflon FEP Tubing is transparent, making it possible to watch

fluid flow. Using different colored tubing can help identify transfer

lines in multisolvent systems. Color coding also allows easy

identification of the tubing thru-hole size. Black FEP tubing is available

for light-sensitive applications (such as enzymatic and chemi-luminescent

reactions) and entering/exiting flow cells.

FEP 1/16" OD tubing holds from 1,000 psi (69 bar) to 4,000 psi (276

bar) depending on the ID. Our 1/8" and 3/16" OD tubing hold to

500 psi (34 bar), while our 1/4" and 5/16" OD tubing hold to 250

psi (17 bar). All of our metric-sized tubing is rated to 500 psi (34 bar).

The recommended maximum operating temperature for Teflon FEP is 50°C. |

| Artikelnummer |

Tubing ID |

Color |

Max. Pressure |

|

| TEFLON

FEP TUBING, 1/16" OD |

| 1474-20 |

.004" (100µm)

ID x 20' |

Black |

4,000 psi (276

bar) (1) |

|

| 1475-20 |

.005" (125µm)

ID x 20' |

Red |

4,000 psi (276

bar) (1) |

|

| 1476-20 |

.006" (150µm)

ID x 20' |

Violet |

4,000 psi (276

bar) (1) |

|

| 1477-20 |

.007" (175µm)

ID x 20' |

Yellow |

4,000 psi (276

bar) (1) |

|

| 1478-20 |

.008" (200µm)

ID x 20' |

Natural |

4,000 psi (276

bar) (1) |

|

| 1479-20 |

.009" (230µm)

ID x 20' |

Blue |

4,000 psi (276

bar) (1) |

|

| TEFLON

FEP TUBING, 1/8" OD |

| 1523 |

.062"

(1.55mm) ID x 10' |

Natural |

500 psi (34 bar) (1) |

|

| 1521BL |

.062"

(1.55mm) ID x 50' |

Blue |

500 psi (34 bar) (1) |

|

| 1521GL |

.062"

(1.55mm) ID x 50' |

Green |

500 psi (34 bar) (1) |

|

| 1521ORL |

.062"

(1.55mm) ID x 50' |

Orange |

500 psi (34 bar) (1) |

|

| 1521RL |

.062"

(1.55mm) ID x 50' |

Red |

500 psi (34 bar) (1) |

|

| 1521YL |

.062"

(1.55mm) ID x 50' |

Yellow |

500 psi (34 bar) (1) |

|

| TEFLON

FEP TUBING, 1/4" OD |

| 1651L |

.156" (4.0mm) ID x

50' |

Natural |

250 psi (17 bar) (1) |

|

| 1650L |

.188" (4.80mm)

ID x 50' |

Natural |

250 psi (17 bar) (1) |

|

| TEFLON

FEP TUBING, 5/16" OD |

| 1652L |

.250"

(6.35mm) ID x 50' |

Natural |

250 psi (17 bar) (1) |

|

| TEFLON

FEP TUBING, 1mm OD |

| |

|

|

|

|

| 1671L |

0.5mm (.020")

ID x 15m |

Natural |

500 psi (34 bar) (1) |

|

| 1671XL |

0.5mm (.020")

ID x 30m |

Natural |

500 psi (34 bar) (1) |

|

| TEFLON

FEP TUBING, 2mm OD |

| 1673 |

1mm (.040")

ID x 3m |

Natural |

500 psi (34 bar) (1) |

|

| 1673L |

1mm (.040")

ID x 15m |

Natural |

500 psi (34 bar) (1) |

|

| 1673XL |

1mm (.040")

ID x 30m |

Natural |

500 psi (34 bar) (1) |

|

| TEFLON

FEP TUBING, 3mm OD |

| 1675L |

1mm (.040")

ID x 15m |

Natural |

500 psi (34 bar) (1) |

|

| 1675XL |

1 mm (.040")

ID x 30m |

Natural |

500 psi (34 bar) (1) |

|

| 1677L |

2mm (.080")

ID x 15m |

Natural |

500 psi (34 bar) (1) |

|

| 1677XL |

2mm (.080")

ID x 30m |

Natural |

500 psi (34 bar) (1) |

|

| TEFLON

FEP TUBING, 4mm OD |

| 1679L |

3mm (.120")

ID x 15m |

Natural |

500 psi (34 bar) (1) |

|

| (1)

Testing conducted with water at room temperature. Use of some chemicals

and at higher temperatures may reduce the pressure limit. Please contact

us for more information |

| HIGH

PURITY TEFLON® PFA TUBING

- 1/16",1/ß", 3/16" and

1/4" ODs Available /

PFA HP and PFA HP Plus Grades Available /

Virtually Contaminant Free

|

| Upchurch Scientific® PFA High Purity

(HP) tubing offers all of the benefits of standard Teflon PFA tubing and

more! This tubing is manufactured from a premium grade of PFA that is one

of the most contaminant-free polymers available. Designed for chemical

environments where purity in the parts-perbillion is needed, this tubing

is perfect for fluid handling systems in the medical, diagnotistics,

pharmaceutical, biotechnology and semiconductor industries. PFA HP Plus

tubing is available in 1/16" and 1/8" OD sizes. This polymer

grade has the same unsurpassed purity of Teflon PFA HP, with increased

ability to withstand repeated flexing and improved resistance to stress

cracking when exposed to aggressive fluorosurfactants. It also offers a

more chemicallystable polymer chain end-capping functional group,

minimizing interaction of this polymerwith ionic species. Furthermore,

tubing made from PFA HP Plus offers even smoother, clearer walls than the

standard PFA HP. The tolerances of our 1/16" OD PFA HP and PFA HP Plus

are ±.001 ", and ±.003"for the 1/8" OD tubing of both

grades. Tolerances for 3/16" OD PFA HIP tubing are ±.003" as

well, with 1/4" OD PFA HP tubing tolerances at ±.004". Please

Note: all tolerance values apply to both OD and ID. |

|

|

360µm

OD TEFLON TUBING

Our capillary-sized tubing is

manufactured from Teflon PFA HP Plus polymer. This tubing offers excellent

chemical compatibility, transparency, very low contaminant levels and is

available in the most commonly-used outer diameter for capillary tubing

applications. Inner diameters range from 50µm to 150µm and tolerances are

an incredible ±.0005" on both the ID and the OD.

To cut this tubing to the length you need, we highly recommend our A-350

Polymer Tubing Cutter. Please Note: once this tubing is held in

place by connecting fittings, extra care must be taken not to stretch the

tubing, as this will likely cause dimensional changes in both the OD and

the ID of the tubing. |

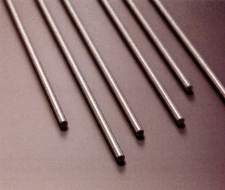

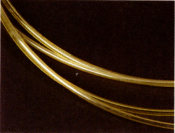

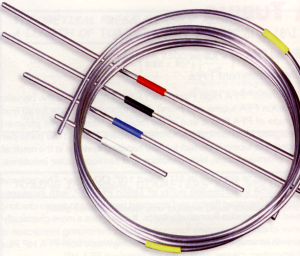

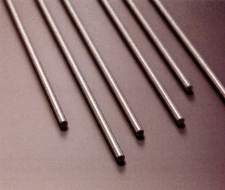

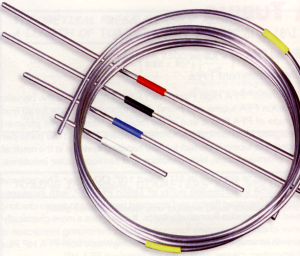

STAINLESS

STEEL TUBING

- Precut

316 Stainless Steel (1) /

The Cleanest, Best Finish Available /

Color-Coded Banding for Easy

Identification

|

(1)

Except our.020 OD Stainless Steel Tubing, which is manufactured from 304

series stainless steel. (2)Except the ,004 ID size, which

has an ID tolerance o1+,002 /-.000" |

Upchurch

Scientific provides seamless, precut stainless steel tubing to meet the

exacting requirements of today's analyses. We machine cut and polish each

end, deburr the inside and outside edges and passivate the tubing. Finally,

we flush reagent-grade methanol through each piece.

Our thorough preparation and cleaning procedure guarantees tubing that is

truly ready-to-use, with flat, burr-free ends and a very clean finish.

This care is important in achieving zero-dead-volume connections and good

chromatographic results. We offer a variety of precut lengths as well as

longer lengths (5' and 25') of some sizes. Cutting the tubing disturbs and

roughens the tubing's end surface, so we recommend using our precut tubing

whenever possible. If you need to cut tubing to custom lengths, we suggest

you then passivate the tubing.

The tolerances of our .020" (510µm) OD tubing are ±.0005" for

both OD and ID. Tolerances for our 1/32" OD tubing are

+.002"/-.000" for the OD and +.000"/-.002" for the

ID.(2) For 1/16" OD tubing, the tolerances are +.002"/.000"

for the OD and ±.001 " for the ID. Our 1/8" OD tubing

tolerances are ±.003 for both OD and ID. |

|

| Artikelnummer |

Lenght |

|

Artikelnummer |

Lenght |

|

| STAINLESS

STEEL (1), .005" (125µm) ID X .020" (510µm) OD |

STAINLESS

STEEL, .004" (100µm) ID X 1/32" (785µm) OD (Red Color

Band) |

| U-119 |

5cm |

|

U-1114 |

5cm |

|

| U-120 |

10cm |

|

U-1115 |

10cm |

|

| U-121 |

20cm |

|

U-1116 |

20cm |

|

| U-122 |

30cm |

|

U-1117 |

30cm |

|

| U-123 |

50cm |

|

|

|

|

| U-125 |

5´(2) |

|

|

|

|

| STAINLESS

STEEL, .006" (150µm) ID X 1/32" (785µm) OD (Yellow Color

Band) |

STAINLESS

STEEL, .008" (200µm) ID X 1/32" (785µm) OD (Clear Color

Band) |

| U-1120 |

5cm |

|

U-1125 |

5cm |

|

| U-1121 |

10cm |

|

U-1126 |

10cm |

|

| U-1122 |

20cm |

|

U-1127 |

20cm |

|

| U-1123 |

30cm |

|

U-1128 |

30cm |

|

| STAINLESS

STEEL, .010" (.25mm) ID X 1/32" (785µm) OD (Blue Color

Band) |

|

| U-1130 |

5cm |

|

|

|

|

| U-1131 |

10cm |

|

|

|

|

| U-1132 |

20cm |

|

|

|

|

| U-1133 |

30cm |

|

|

|

|

| STAINLESS

STEEL, .015" (0.40mm) ID X 1/32" (785µm)

OD (Green Color Band) |

STAINLESS

STEEL, .018" (0.45mm) ID X 1/32" (785µm)

OD (Black Color Band) |

| U-1140 |

5cm |

|

U-1145 |

5cm |

|

| U-1141 |

10cm |

|

U-1146 |

10cm |

|

| U-1142 |

20cm |

|

U-1147 |

20cm |

|

| U-1143 |

30cm |

|

U-1148 |

30cm |

|

| STAINLESS

STEEL, .005" (125µm)

ID X 1/16" OD (Red Color Band) |

STAINLESS

STEEL, .007" (175µm)

ID X 1/16" OD (Black Color Band) |

| U-152 |

5cm |

|

U-126 |

5cm |

|

| U-153 |

10cm |

|

U-127 |

10cm |

|

| U-154 |

20cm |

|

U-128 |

20cm |

|

| U-155 |

30cm |

|

U-129 |

30cm |

|

| U-156 |

0.5m |

|

U-130 |

0.5m |

|

| U-157 |

1m (2) |

|

U-131 |

1m (2) |

|

| U-158 |

5` (2) |

|

U-108 |

5` (2) |

|

| U-160 |

25`(2) |

|

U-161 |

25` (2) |

|

| STAINLESS

STEEL, .010" (0.25mm) ID X 1/16" OD (Blue Color Band) |

STAINLESS

STEEL, .020" (0.50mm) ID X 1/16" OD (Yellow Color Band) |

| U-111 |

5cm |

|

U-101 |

5cm |

|

| U-112 |

10cm |

|

U-102 |

10cm |

|

| U-113 |

20cm |

|

U-103 |

20cm |

|

| U-114 |

30cm |

|

U-104 |

30cm |

|

| U-132 |

0.5m |

|

U-134 |

0.5m |

|

| U-133 |

1m (2) |

|

U-135 |

1m (2) |

|

| U-106 |

5` (2) |

|

U-105 |

5` (2) |

|

| U-162 |

25` (2) |

|

U-163 |

25` (2) |

|

| STAINLESS

STEEL, .030" (0.75mm) ID X 1/16" OD (White Color Band) |

STAINLESS

STEEL, .040" (1.0mm) ID X 1/16" OD |

| U-115 |

5cm |

|

U-138 |

5cm |

|

| U-116 |

10cm |

|

U-139 |

10cm |

|

| U-117 |

20cm |

|

U-140 |

20cm |

|

| U-118 |

30cm |

|

U-141 |

30cm |

|

| U-136 |

0.5m |

|

U-142 |

0.5m |

|

| U-137 |

1m (2) |

|

U-143 |

1m (2) |

|

| U-107 |

5` (2) |

|

U-144 |

5` (2) |

|

| U-164 |

25` (2) |

|

U-165 |

25` (2) |

|

| STAINLESS

STEEL, .046" (1.15mm) ID X 1/16" OD |

STAINLESS

STEEL, .080" (2.0mm) ID X 1/8" OD |

| U-145 |

5cm |

|

U-815 |

15cm |

|

| U-146 |

10cm |

|

U-825 |

25cm |

|

| U-147 |

20cm |

|

U-800 |

1m (2) |

|

| U-148 |

30cm |

|

U-803 |

3m

(2) |

|

| U-149 |

0.5m |

|

U-805 |

5m

(2) |

|

| U-150 |

1m (2) |

|

|

|

|

| U-151 |

5` (2) |

|

|

|

|

| (1)

Our 020 OD tubing is made of 304

series stainless steel All other tubing on this page is made o1316 series

stainless steel. (2) All Stainless Steel tubing longer than 1 m is

coiled |

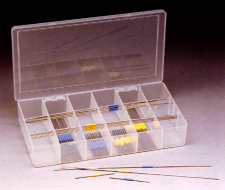

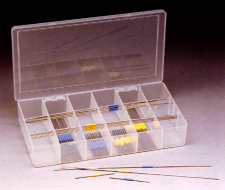

PRECUT

STAINLESS STEEL TUBING KITS

|

TITANIUM

TUBING

- Excellent

Alternative to Stainless Steel Biocompatible

|

Try Upchurch

Scientific® pre-cut Stainless Steel Tubing Kits, which contain some of

the most popular 1/16" OD tubing sizes at a discount compared to

purchasing the pieces individually. Each kit includes a handy storage

container, great for keeping your tubing organized and close at hand.

Our 316 stainless steel tubing meets the highest quality standards in the

industry. Each tubing piece features polished, burr-free ends and includes

a color-coded band for easy ID identification. |

Metal tubing

is necessary in certain high pressure or high temperature applications,

but stainless steel cannot be used in some cases (such as with protein

analysis). Titanium is an excellent biocompatible alternative.

Upchurch Scientific's commercially-pure, seamless titanium tubing is

carefully cut to ensure a square, burr-free end. The tolerances of our

titanium tubing are: +.002" and -.000" for the OD, and ±.001"

for the ID.

Please be aware of the drawbacks of titanium tubing. It is brittle, so

care must be taken when bending. Also, acids can cause physical stress and

potential fracturing along the wall of the tubing. |

|

|

CAPILLARY

POLYMER TUBING CUTTER

|

|

| The Upchurch

Scientific® A-350 Cutter is designed to cut capillary-sized polymertubing.

The cutter makes clean, perpendicular cuts without collapsing thin

capillary walls. A set of ten tubing sleeves, required for cutting, are

included with each cutter, along with five replacement blades. The

included tubing sleeves are for cutting 360µm OD polymer capillary tubing.

Alternative sleeves are available for cutting 510µm and 1/32" OD

tubing. All tubing sleeves are 2" long and are made of FEP Teflon®. |

|

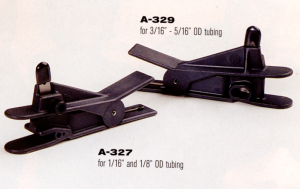

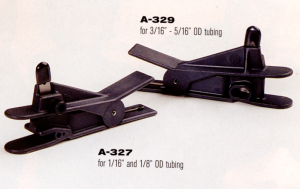

POLYMER

TUBING CUTTERS

- For 1/16", 1/8",

3/16", 1/4" and 5/16" OD tubing

|

| A flat, 90º,

burr-free cut is difficult to obtain with most commercial polymer tubing

cutters. Upchurch Scientific has designed several tubing cutters

specifically to cut polymer tubing. This line of tubing cutters includes a

standard cutter for 1/16" and 1/8" OD tubing (A-327), and

another for large bore tubing (A-329). Each has guide holes to ensure

precise cutting. These cutters are durable, reliable, and easy to operate.

Five replacement blades are included with each cutter. |

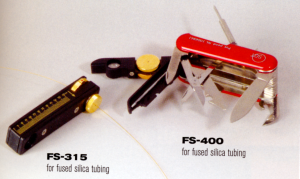

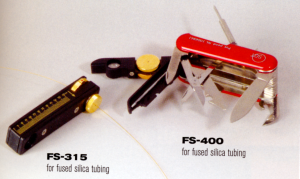

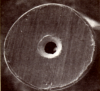

FUSED

SILICA TUBING CUTTERS

|

|

We offer a

precision cutter for fused silica tubing - SGT's Shortix™

Cutter (FS-315). This cutter ensures clean, trouble-free cutting of fused

silica tubing, providing better cuts than any other product on the market.

It also includes a built-in magnifying glass to examine the cut tubing

ends. Order the FS-315-02 Maintenance Kit, as needed, to replace a worn

or damaged cutting wheel.

When using traditional fused silica tubing cutters, only a small part of

the tubing wall is scratched, then the tubing is snapped in two, often

resulting in ajagged, uneven cut. With a Shortix Cutter, a clean cut is

made every time, regardless of skill or experience, as the cut is made by

rotating a diamond blade around the entire circumference of the tubing. |

We

now also carry the Shortix Plus Cutter for fused silica tubing (FS-400).

Built into the base of a genuine Swiss Army®"

knife, the Shortix Plus includes a Shortix fused silica tubing cutter with

built-in magnifying glass, ferrule remover, septum hook and round file,

plus standard Swiss Army knife features, such as: a knife blade, screw

drivers, multipurpose wrench, awl, scissors, tweezers, can opener, nail

file, and toothpick. This cutter also comes with a nylon belt loop

carrying case.

Please Note: the FS-315 and FS-400 Fused Silica Tubing Cutters are

designed to cut only tubing with ODs of 350µm - 780µm and IDs of 100µm -

350µm |

| Artikelnummer |

Beschreibung |

Menge |

|

|

CAPILLARY

POLYMER TUBING CUTTER

|

| A-350 |

Capillary Polymer

Tubing Cutter (1) for 360µm - 1/32" OD tubing Includes

(1) F-262x 10-pack of sleeves and (1) M-438-03 wrench |

|

|

| F-262 |

Replacement

Sleeves for A-350,.0155" ID, Green, for cutting 360µm OD tubing |

Stck.;

Mindestabnahme 25 Stück |

|

| F-264 |

Alternative

Sleeves for A-350,,02 1" ID, Natural, for cutting 510µm

OD tubing |

Stck. |

|

| F-267B |

Alternative

Sleeves for A-350-033" ID, Blue, for cutting 1/32" OD

tubing |

Stck. |

|

| FUSED

SILICIA TUBING CUTTERS |

| FS-315 |

Shortix Precision

Fused Silica Tubing Cutter |

|

|

| POLYMER

TUBING CUTTERS |

| A-327 |

Standard Polymer

Tubing Cutter (2) for 1/ 16" and 1/8" OD tubing |

|

|

| A-329 |

Large Bore

Polymer Tubing Cutter (2) for 3/16" - 5/16" OD tubing |

|

|

| A-328 |

Replacement

Blades for A-327 and A-329 |

5-pk |

|

| (1)

Includes (1) A-351 5-pack of replacement blades (2) Includes

(1) A-328 5-pack of replacement blades |

Precut Tubing

Precut Tubing Tubing cut by a commercially available

tubing cutter

Tubing cut by a commercially available

tubing cutter File Cut tubing

File Cut tubing